| Product Name | Enhanced Precise Micro Adjust Six Color Six Station Double Wheel Overprinting Screen Printing Machine S662L |

| Item NO. | SPM-S662L-006255 |

| Weight | 215 kg = 473.9939 lb = 7583.9018 oz |

| Volume | 1.25 CBM |

| Category | Screen Printing > Screen Printing Machine > Multi Color |

| Creation Time | 2020-10-08 |

006255 S662L Enhanced Precise Micro Adjust Six Color Six Station Double Wheel Overprinting Screen Printing Machine

It is mainly used for the six colors T-shirt overprinting,it is configured with six screen frame chucks and six t-shirt pallet stations;

Both the pallet part and the screen frame part can rotate independently at 360 degree;Users can operate at any station; Each screen frame chuck is configured with manual micro adjusting knobs, to make sure the overprinting accurate.Adjustable reinforced support beam is installed at the bottom of each pallet,and it can make the pallet more stable, the printing more accurate.

If one dryer is placed on a station to flash dry the surface, two users are familiar with the machine, they can print 30-50 pieces six colors t-shirts each hour .

This machine is manual mobile screen frame to match color,all the screen frames’position is correct to any one pallet , the other one pallet will be correct , then the user can start overprinting.There is no need to correct the position of the color one by one.

The functions and characters :

1. The chuck of the screen frame can rotate at 360 degree;Users can operate at any station or any pallet position;

2. Users can finish all the screen frame’s overprinting positioning at any pallet station,

All the screen frames’position is correct to any one pallet , the other one pallet will be correct , then the user can start overprinting.There is no need to correct the position of every pallet.

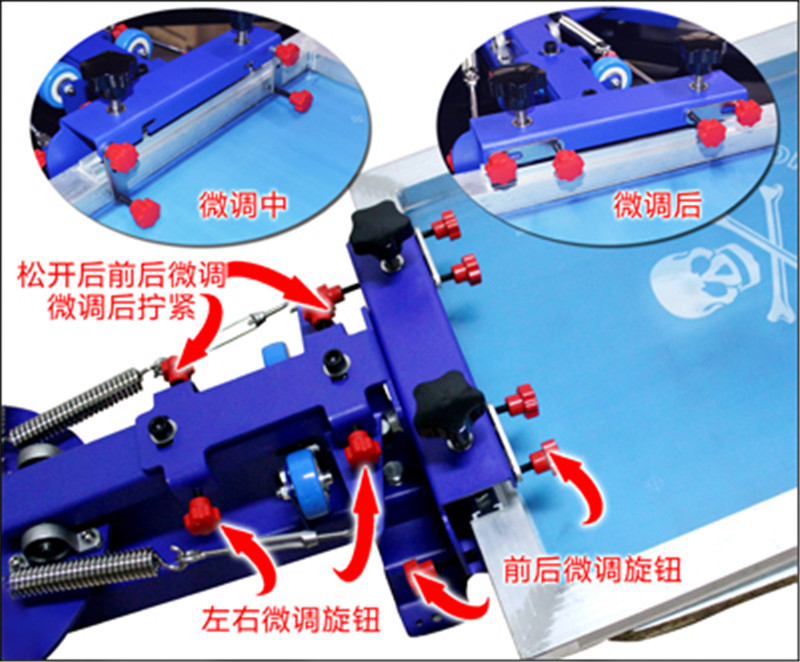

3. Each screen frame fixing device is configured with eight micro adjust knobs. By using the knobs ,user can micro adjust the screen frame from front to back , from left to right .It can make the overprinting more simple and more accurate.

4. Each screen frame’s fixing device is equipped wth precise positioning wheel,when the positioning iron on the arm placed in positioning wheel closely, it can ensure the printing precision

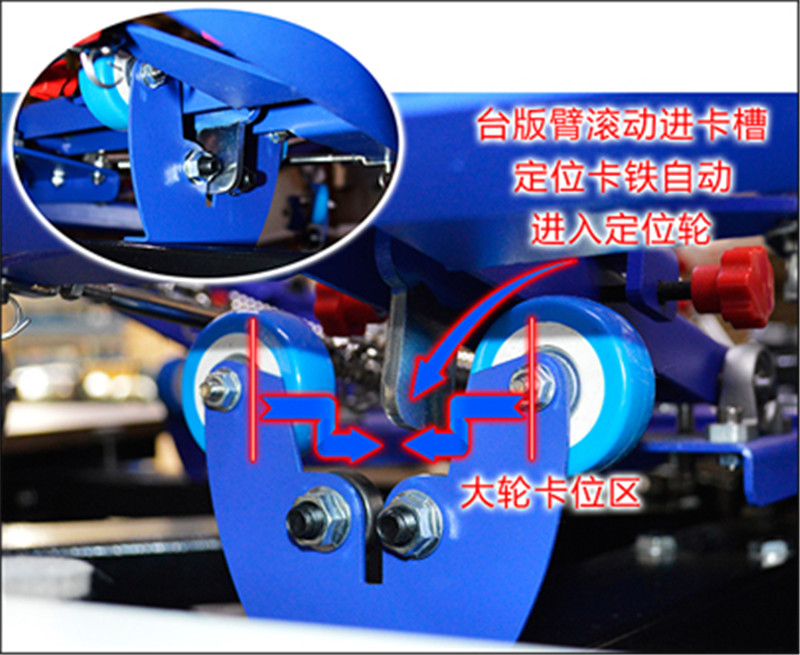

5. Each screen frame’s fixing device is equipped wth big lock wheel, screen frame arm can easily fall into the metal positioning wheel when touch the two big lock wheels ,and it also can prevent the direct collision between the positioning iron and the metal positioning wheel

6. Each screen frame’s fixing device is equipped wth adjustable height chuck positioning knobs and adjustable height knobs when lift up the acreen frame

7. According to the weight of the screen frame, spring tension can be adjusted by the basket screws to achieve balance;

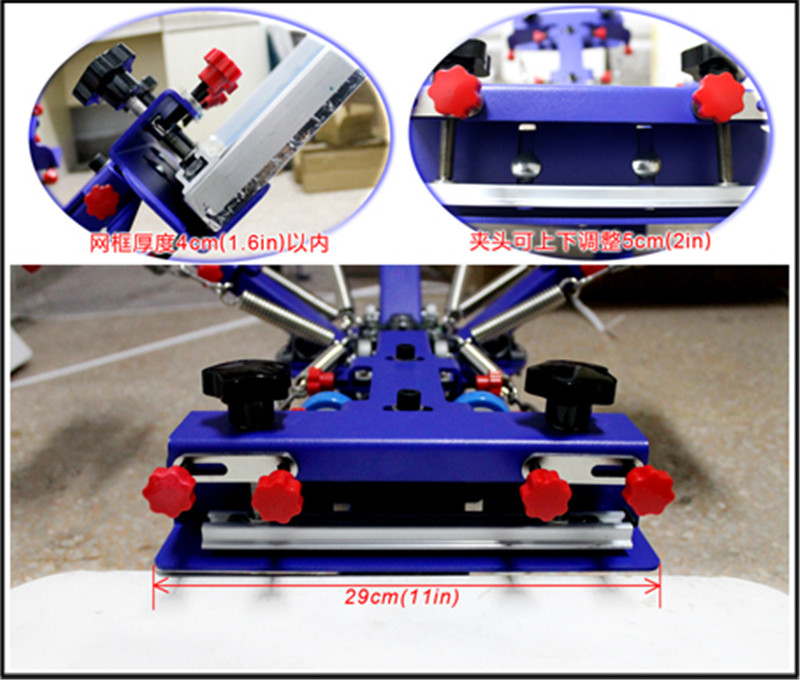

8. Screen frame chuck’s width is (11in) 29 cm ; It is suitable for screen frame with outside size within (24 in) 60 cm and screen frame with thickness size is within 4 cm (1.6 in) ;

9. The screen frame chuck can be adjusted up to 5cm(2in) according to the height of the substrate.

10. Screen frame chuck knob fix the screen frame together with the special aluminum alloy plate, and it can be fit closely and be more stable;

11. The chuck of the screen frame can rotate at 360 degree;Users can operate at any station;

12. The pallet and pallet installation beam is connected by adjustable height connections,users can

adjust the height of the pallet within 3cm(1in)according to need.

13. The pallet can move 10cm(4in)from front to back by the connections at the bottom of the pallet.

14. There is reinforced adjustable supporting beam installed at the bottom of each pallet.By tightening the screws at the bottom of the supporting beam,user can make the pallet be more stable,and it can also make sure the printing accurate.

15. T-shirt type pallet of the machine is 55 cm (22 in) long, 45 cm(18in) wide, the thickness is 1.8 cm (0.7 in); Using furniture surface melamine high density board, the surface with small pits, and it is more suitable for printing T-shirt when scraping the pallet glue.

16. There are five supporting skew beams at the bottom of the machine .The machine is configured with 10 machine rack supporting feet, and it can adjust the height of the whole machine within 4cm (1.6in) .

17. The machine adopts advanced electrostatic spraying process, various parts using stainless steel, aluminum alloy, nickel and zinc plating technology. They are corrosion resistance, no fading, easy to clean, maintain color and finish for a long time, and it can use for a long time with no rust.

18. All machines are configured with a full set of tools to install the machine; There is no need to prepare for other tools to complete the installation; Equipped with installation diagram and the packing list, parts installation location is very clear; All machines are configured with installation CD and operation video, it is more convenient for the user to install and use the machine .There are still spare parts in the box for users to change .

No related record found